9 Tips for Efficient Warehouse Design

They say time is money, and that’s certainly true of warehouses. Every moment lost due to poor warehouse design is another package not sent, another piece of inventory not stored. Another unsatisfied customer. Warehouses are critical to keeping entire businesses running smoothly, and your business could suffer if your warehouse isn’t designed properly. Here are some warehouse design tips to promote efficiency.

Consider Your Needs

How much inventory do you expect to hold once your warehouse is running? How much do you plan to hold in a year? Two years?

Be clear about the goals and objectives of your warehouse design. What’s most important to your business? What’s absolutely essential, and what can you live without?

Thinking critically about your needs beforehand can save you money and make your warehouse more efficient in the future.

Focus on Safety

Technically this isn’t an efficiency tip, but there’s something more important than efficiency-safety.

Before anything else, focus on safety. According to the Occupational Safety and Health Administration (OSHA), The fatal injury rate for the warehousing industry is higher than the national average for all industries. They list safety hazards like improper forklift use, poor fire safety, and many other concerns that warehouse managers have to be on the watch for. Read their post for tips.

Efficiency is important, but protecting your employees is even more so.

Follow Local Building Codes

It’s critical that you follow the building codes in your area to the T. Don’t take shortcuts. If you’re caught, you may have to make major renovations. If you aren’t caught, you may create a safety hazard.

Consider Your Location

Ideally, you should build your warehouse close to where your customers live to minimize shipping costs. You will likely have addresses for many of your customers that they gave you when ordering. Also, if your business already has other warehouses, think about where they’re located and be strategic when choosing a location for this one.

Rural places will usually have cheaper land, but these places may have poor access to transportation which can cost you in the long run. You’ll need to take both the cost of the property and the ease of transportation into account when deciding where to build your warehouse.

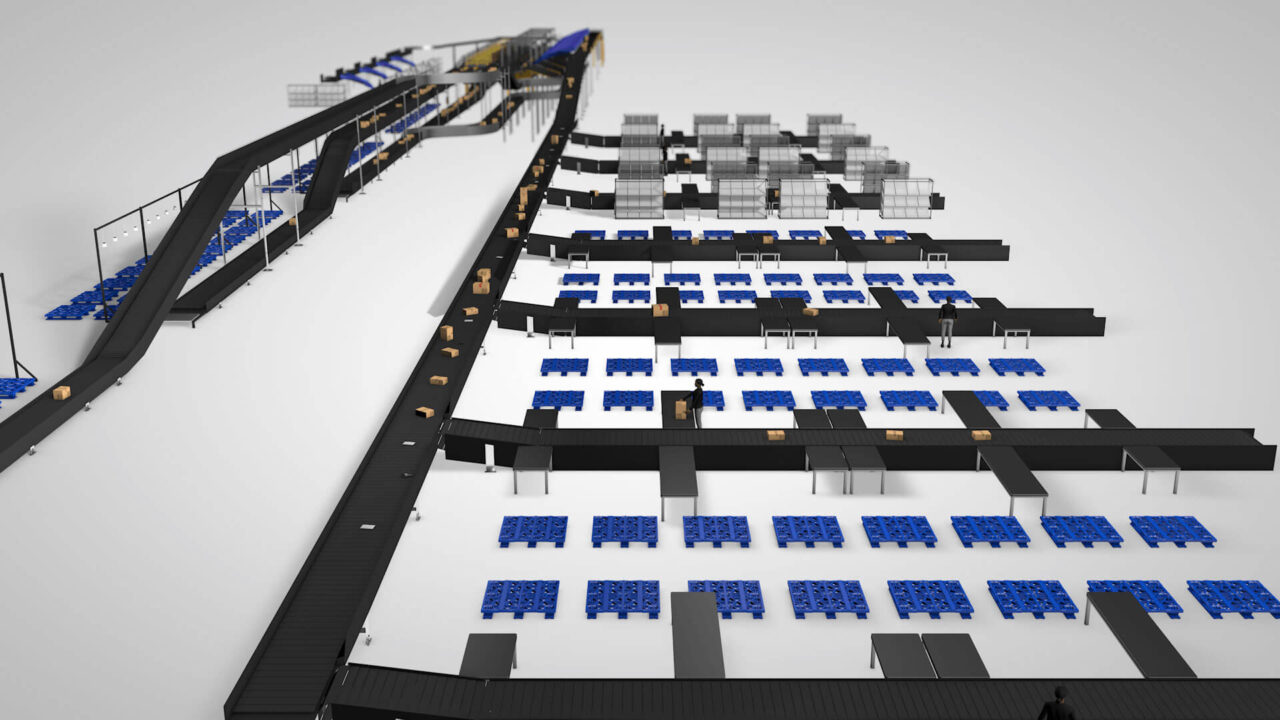

Invest in Conveyor Systems

Conveyor systems can cut down on the amount of time and man-hours it takes to transport materials through your warehouse. There are a lot of different types of systems. See some here.

Use a Warehouse Management System

A Warehouse Management System (WMS) is a software that helps keep track of all your inventory. Using this data, your WMS can give you recommendations about how to improve your warehouse. Maybe you could organize your inventory in a better way. Maybe your isles could be arranged differently. Computer programs can sometimes find counter-intuitive solutions that humans overlook.

Automate

There are different levels of warehouse automation. Not every warehouse needs a supercomputer running thousands of little robots.

Yet many warehouses could benefit from increased automation which will reduce mistakes and decrease the need for labor. It’s less expensive than you probably think, and it should pay for itself in just a couple of years. Automation isn’t right for every warehouse, but it may be right for yours and could save you a lot of time and money. Click the link above to learn more.

Remain Flexible

No one knows the future. We make our best guesses, but unforeseen problems and opportunities occur all the time. Maybe sales will unexpectedly double next year. They might drop by a third. Maybe the company will be bought out by a new manager who wants to completely change directions.

Your warehouse should be flexible enough to adapt to unpredictable circumstances. Make sure you have enough dock doors for example. Also, mezzanine floors can make your warehouse more efficient and flexible by helping you utilize your space.

You can also buy a flexible electric system like a busbar strip. Also, consider buying more versatile equipment as opposed to niche-use machines.

Talk to Experts

Even if you’ve designed a warehouse before, getting another set of eyes never hurts. Talk to experts about the layout, and ask them for advice. Anytime people collaborate, one person may notice something the other missed.

You can ask your material handling company, and you can call us. DCS has almost 40 years of experience in the industry, and we’ve worked on both small projects and projects worth tens of millions of dollars. We’ll help you design your warehouse or review the plans you already have.