The functionality of your conveyor systems will have a direct impact on the success of your operations. Streamlining the picking and sorting processes can provide a wide range of benefits.

Small mistakes or bumps in the road might not seem like too big of a deal. However, these little hiccups can add up to large problems when repeated multiple times every day.

Delays in picking and sorting translate to shipping delays, which leads to unhappy customers and vendors.

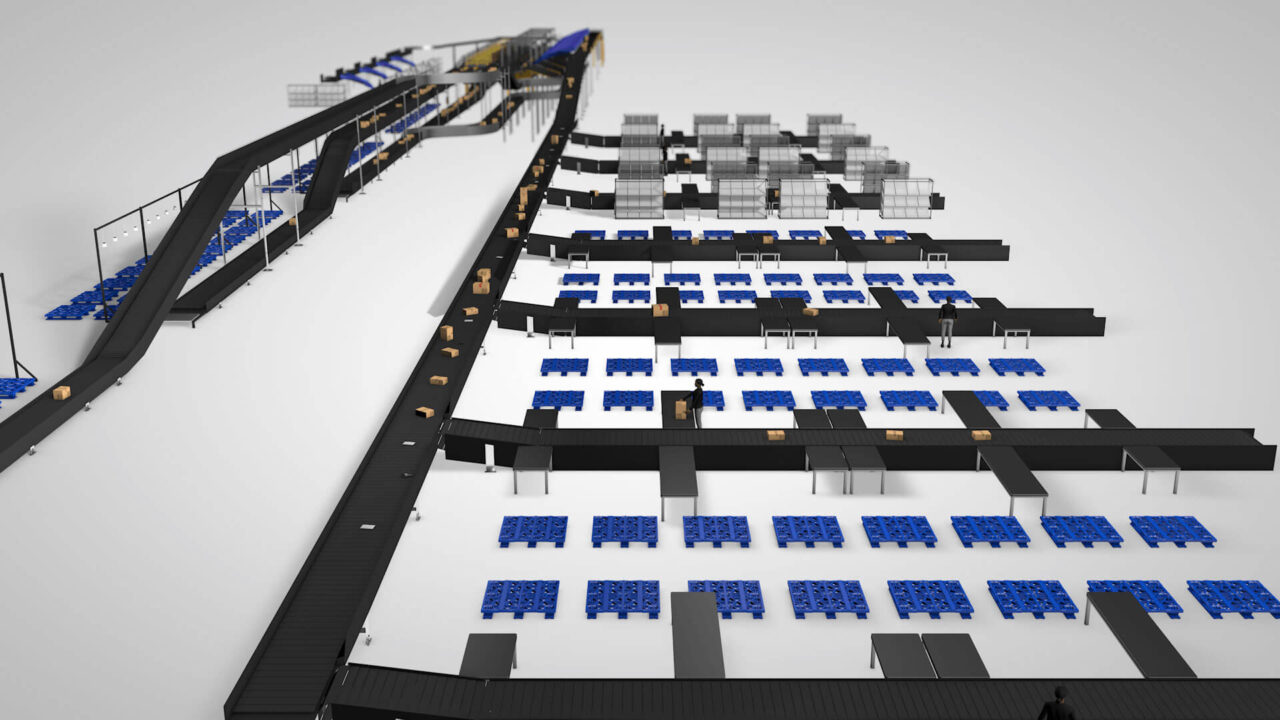

A conscientious conveyor design helps to streamline these processes. New technology affords companies capabilities that weren’t previously available. Taking the time to plan out a conveyor design specifically for your space and your needs ensures proper utilization of these capabilities.

However, your needs can change over time. So how do you know when it’s worth your time to reconfigure your conveyor design?

Here are six signs it’s time to update your conveyor design:

- Demand is Increasing

- Frequent Repairs

- An Influx of New Materials

- Inefficient Processes

- New Functionality Is Needed

- Numerous Errors

Demand is Increasing

Every system is going to have its limits. When your business continues to grow and demand increases, your infrastructure could reach its maximum capacity for efficiency.

This issue isn’t going to show itself as a general breakdown of your entire system. Instead, you’ll notice shipping times will begin to grow. Items could potentially be lost, and employees might become increasingly stressed or overworked as they attempt to keep up with their duties while demand overwhelms them.

Updating your conveyor design will account for the increase in demand. Your capacity for handling the increased workload will be increased with the help of expert designers and updated equipment.

Frequent Repairs

Conveyor systems see a lot of use. This use creates wear, which leads to occasional breakdowns if not kept up with routine preventative maintenance. An expert conveyor company’s assistance will help reduce the wear on your systems and provide guidance on maintaining your systems best.

A conveyor system that requires frequent repairs despite these best practices might simply be overworked. Additional safeguards can be put in place by an intentional and well-designed conveyor system to prevent this extra wear.

Re-visiting your conveyor design ensures that your equipment has the support it needs to continue operating smoothly and efficiently.

Visit DCS to learn more about updating your conveyor design today!

The Influx of New Materials

A growing business frequently includes new and exciting products and offers. These changes are almost impossible to predict, meaning an old conveyor system simply won’t fit new products.

Your conveyor system’s size and shape can be altered to fit any new materials that need to be sorted. Transporting these materials requires a system that will allow smooth passage and does so quickly and efficiently.

Your conveyor system needs to be able to handle the various objects and materials you need to process. An updated conveyor design makes sure any, and all challenges can be met.

Inefficient Processes

As we mentioned earlier, any bumps in the road can create larger problems later in the process. Even small issues will grow large over time, like a snowball rolling down a hill.

A streamlined operation will continuously look out for these issues and find ways to make processes more efficient. Wasted manpower, frequent mistakes, or costly repairs can bring down the profitability of your entire operation.

Consulting with a conveyor system design professional helps identify any issues you might not even notice, and any problem that can be fixed will benefit your company.

New Functionality Is Needed

Another aspect of expanding your services is that new processes will need to be instituted. While there are always going to be a variety of ways any singular task can be completed, there are also going to be some methods that are better than others.

An updated conveyor design system can efficiently address any new functionalities needed to complete these new processes. Fulfillment solutions, parcel handling, and material handling can be complicated processes that greatly benefit from a professional’s advice.

Numerous Errors

Anybody who has tried to cook too many items at once knows that becoming flustered will lead to mistakes. There will come a point where you are asking too much of your employees and your conveyor system.

The number of mistakes will increase as this demand continues to rise. Not only will this lead to lost items, damaged materials, and stressed employees, it will create a negative experience for your customers.

Updating your conveyor design addresses the increased need so you can get the right items to the right people with the need to redo erroneous processes.

Contact DCS today!