Material Handling Systems Explained

Material handling is a term that we may have heard in passing without fully understanding it. We may have a vague idea of what it entails, but many do not think about it much beyond that. However,material handling systemsare incredibly important to the way our society functions.

That might sound grandiose, but it is true. Everything you see on a store shelf has gone through a material handling system, which is even true for the materials that make up the shelves. In fact, most things you come into contact with have gone through the supply chain with the help of a material handling system.

But what is the supply chain, and what are material handling systems? Let’s look into the specifics of how these systems propel our everyday lives.

What Are Material Handling Systems?

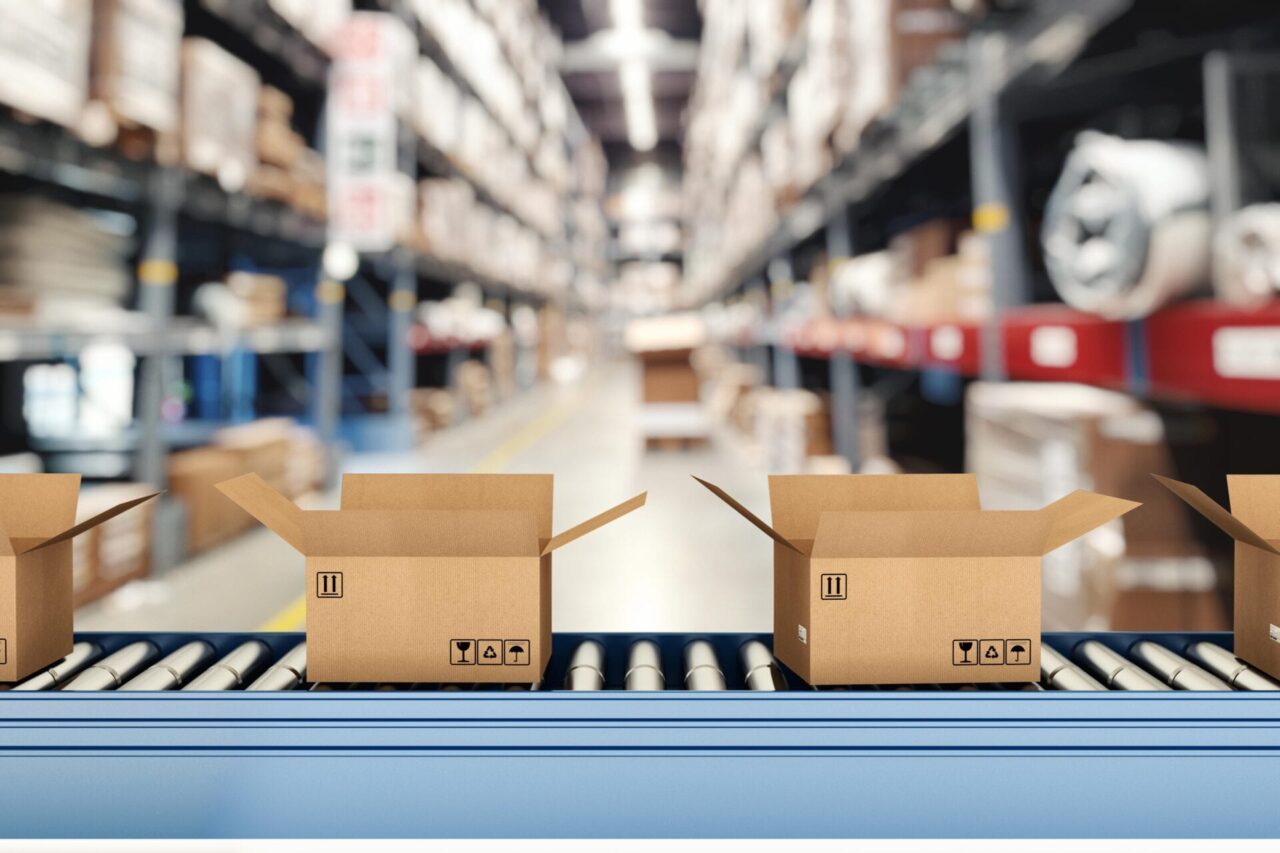

To understand this question, we have to understand the supply chain first. The supply chain is simply a series of processes that encompass everything from the production to the distribution of a product- which essentially covers the trip a product takes from the factory to your doorstep.

The supply chain consists of several different stages. First, raw materials are sourced by a supplier, which are then put into production. These products are frequently sent to a storage facility before a distributor moves them to either the direct consumer or a sales facility, connecting with the consumer.

From manufacturing to consumption, this process is performed throughmaterial handling systemsand includes the protection, control, storage, and movement of the materials and products.

The supply chain is the path products take to get to you. Material handling systems are the mechanisms that take them there. Beyond that, material handling also involves the disposal of these materials.

How It Works

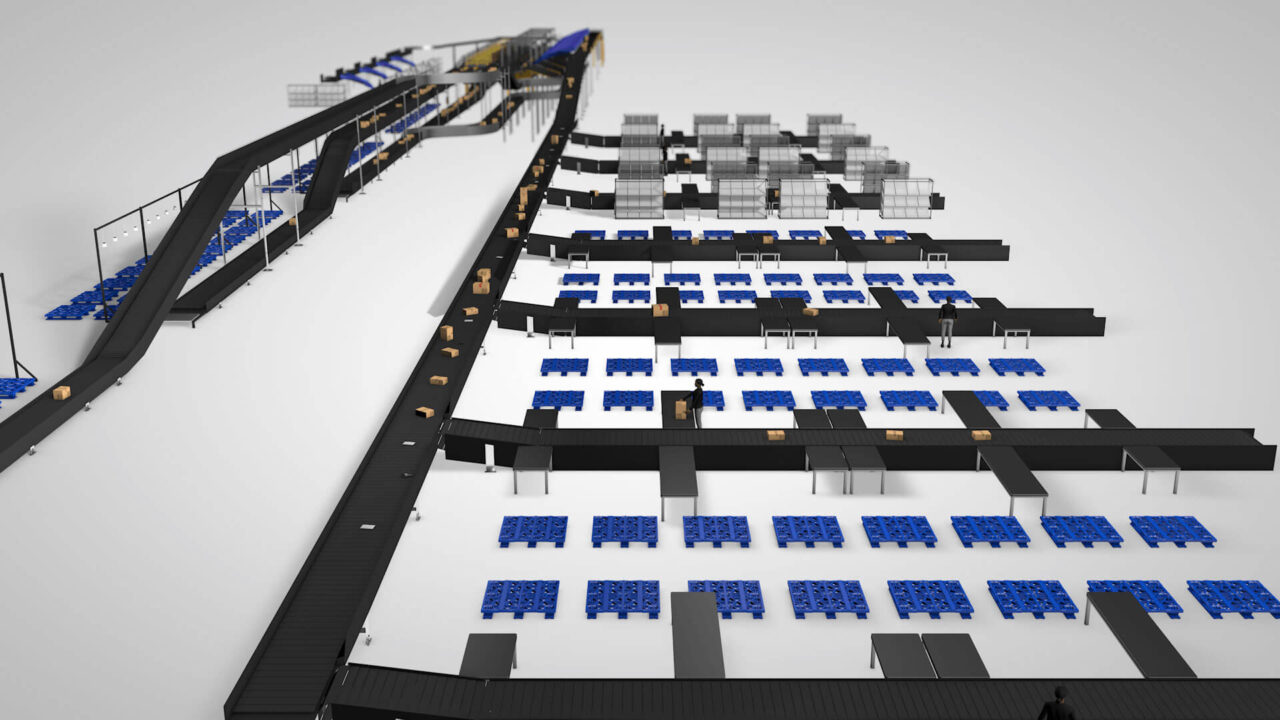

Since material handling systems cover many different services within the supply chain, various mechanisms and services are used to complete each specialized task, such as manufacturing, storage, distribution, and fulfillment.

With the continuing advancements in technology come the evolution of the tools and equipment used to complete these tasks, which increases efficiency benefiting both the consumer and the supplier. The following are specific areas of a material handling system that can help the consumer receive their product sooner and make the supplier’s process more efficient while reducing their overall costs.

Automation

The main advantage of warehouse automation is efficiency. It helps you streamline your human resources by putting them to work on more important tasks. Menial and repetitive tasks fail to make use of the full potential of your employees.

Warehouse Automation can include everything from simple transportation conveyors to high-speed sortation. To understand what level of automation best suits your needs, you must first fully understand the challenges you may have regarding your operation. Some of the questions you should ask yourself are do I have a labor shortage due to resource availability in my area, have I outgrown my current manual processes, or has my eCommerce business taken off requiring me to handle my inventory more frequently to simply get an order filled? All of these challenges can be managed by some type of material handling systems automation.

Assisted Working Equipment

Human power can accomplish a great deal of work, but technology’s assistance makes it substantially more efficient. This includes lifting equipment,conveying equipment, storage equipment, and ergonomic equipment to increase safety.

Software

The ability to track products is an essential aspect of material handling systems. Orders are filled much quicker when the exact location of items within a warehouse is known, allowing real-time updates for consumers to expect their products’ arrival. Information saves time, and time is money. Efficient processes rely on adequate information, and the systems will continue to grow more efficiently as data becomes more readily available.

Sustainable Green Solutions

A focus on sustainability has arisen in the last few years due to many different factors-public perception, environmental impact, and legislation. Aside from that, sustainable practices within material handling systems can save companies money. Methods such as load consolidation and route planning optimize the distribution efforts, which diminishes the effect on the environment and saves on resources used by the company.

Outsourcing Material Handling

Third-party logistics (3PL) is becoming an increasingly popular way for companies to navigate the supply chain and use professionals with well-established material handling systems. DCS assists 3PL companies with automated warehouse services to streamline their storage needs and can help you too.

Contact us today to see how our Supply Chain Consultants can improve your material handling system!