5 Tips for Learning the Material Handling Industry

by Alyssa Colvin

Learning any new industry can be daunting. New people. New processes. New everything it feels like. I would know. I found myself new to the Material Handling Industry just a short 6 months ago. Good news is I’ve compiled a list of tips & tricks to help anyone in learning all things Material Handling. Think of it as a cheat sheet. Full disclosure, this won’t have all the answers, but it’s a good starting point. With all of that said, here are 5 tips for learning the MH Industry.

- Learn the Vocab

I’ll never forget my first project meeting. The team could have been speaking another language, and I would have understood the same amount. Commissioning versus beneficial use versus project go-live. There are a ton of industry specific terms. How I managed through this learning curve was to write down any terms I didn’t know. After the meeting, I’d ask someone to explain what each term meant. Each day, I had new terms that I didn’t know, but at the same time, each day I was adding to my personal Material Handling dictionary of terms I did understand.

- Learn the Equipment

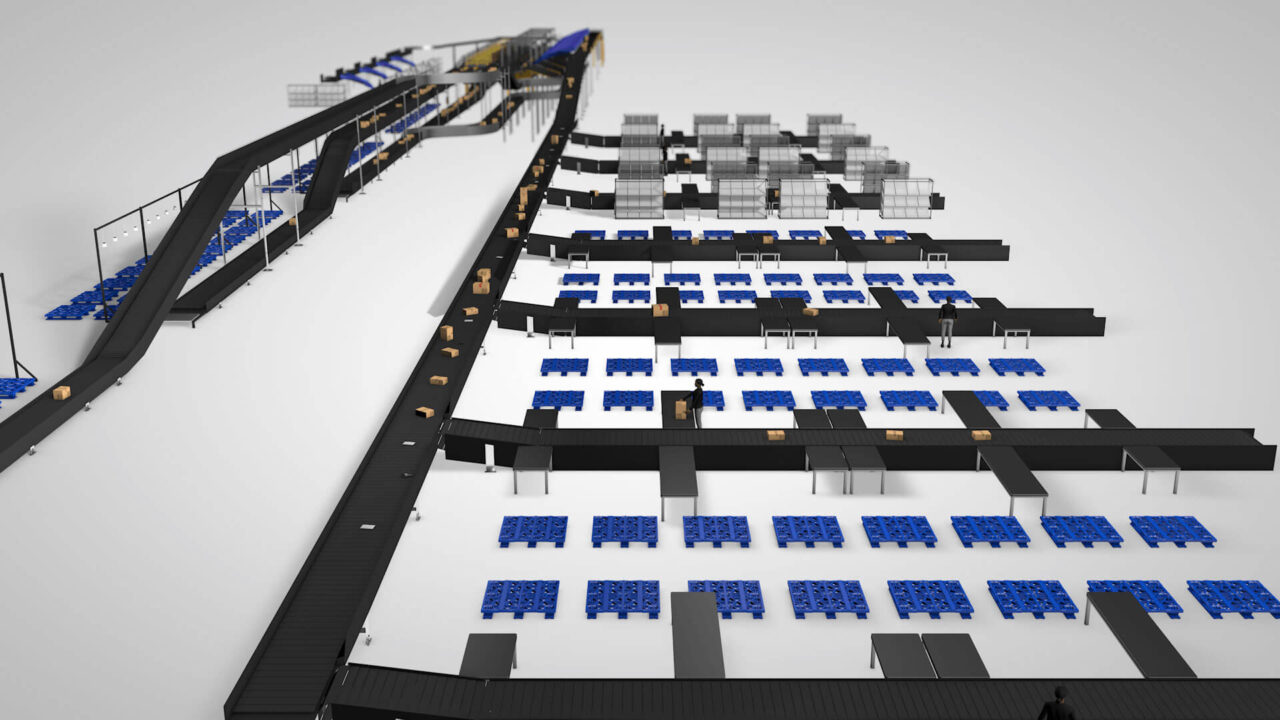

This goes with learning the vocab, but there is so much equipment that I had to put it as a separate bullet. Pulleys, belting, gravity, transfer plates, power curves, QA chutes. There is a lot of equipment that goes into a system. Whenever you’re unsure about equipment, I’ve found it best to ask a coworker. More times than not, you’ll find someone who can explain what it is, what it does, and why it’s important to have. My next suggestion is to turn to the internet. Google and YouTube will become your friend. Find the equipment online. Watch a video. Knowing what a piece of equipment is is one thing. Understanding its function is another. Videos help with that. Lastly, if you have the option to go to site, say yes. Go see a conveyor system in real life. Don’t talk about dumpers and dumper chutes, go see a dumper in action.

- Be a Sponge

You will be surrounded by people who have experience. Learn from them. Engage in conversation. Some of the biggest tricks I’ve learned have come from comments in passing. If you have a day where you’re shadowing someone, take notes on their processes. Why do they something the way they do? How do they handle certain situations? Understand that in every situation, there is a learning opportunity. Soak it in.

- Ask Questions

If someone is talking about something you don’t understand, the worst thing you could do is act like you’re following along. Speak up. Ask questions. The people around you are accustomed to the industry, but you aren’t. They will forget some topics aren’t easy to comprehend when you have no exposure or experience with it.

- Manage your Expectations

It’s easy to get discouraged when everything is so new. Don’t fall into the trap of feeling like you’re not making any progress. Beyoncu00e9 didn’t become a superstar overnight. You’re not going to be an expert in a week. Each day you’ll learn something new, and honestly, that’s the fun part. Continue to push forward, ask questions, show up each day, but understand that time is your biggest asset. The more time you spend learning the Material Handling Industry, the more comfortable you’ll feel. Before you know it, you’ll be the person explaining equipment, answering questions, and helping others adjust to this new, ever-changing industry.

_

With a strong background in logistics, Alyssa has expanded her career to the Material Handling Industry as a Buyer for DCS. She enjoys working in a team environment while helping provide supply chain solutions for a variety of customers. Outside of work, you can catch Alyssa walking her lab, exploring new places, and rooting on the Crimson Tide.

With a strong background in logistics, Alyssa has expanded her career to the Material Handling Industry as a Buyer for DCS. She enjoys working in a team environment while helping provide supply chain solutions for a variety of customers. Outside of work, you can catch Alyssa walking her lab, exploring new places, and rooting on the Crimson Tide.

With a strong background in logistics, Alyssa has expanded her career to the Material Handling Industry as a Buyer for DCS. She enjoys working in a team environment while helping provide supply chain solutions for a variety of customers. Outside of work, you can catch Alyssa walking her lab, exploring new places, and rooting on the Crimson Tide.

With a strong background in logistics, Alyssa has expanded her career to the Material Handling Industry as a Buyer for DCS. She enjoys working in a team environment while helping provide supply chain solutions for a variety of customers. Outside of work, you can catch Alyssa walking her lab, exploring new places, and rooting on the Crimson Tide.