This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

CASE STUDY: Meyn Americas’ Operations Leaders Share Their Automation Journey with DCS

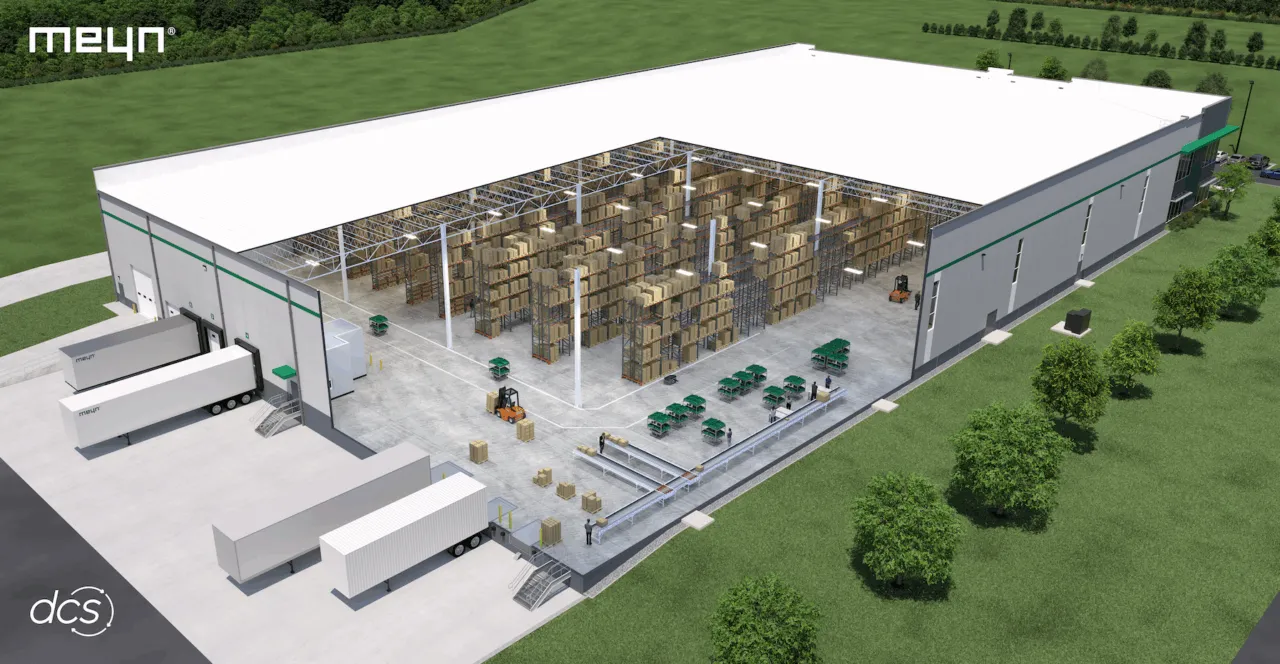

Meyn Americas LLC, a subsidiary of Meyn Food Processing Technology B.V., engaged DCS to design and install a new distribution and fulfillment system for its new, Green Globes-certified spare parts distribution center (DC) located in Westminster, South Carolina.

The system incorporates autonomous mobile robots (AMRs) for order picking and inventory put away, and a shipping sortation conveyor. Additionally, DCS deployed DATUM, its proprietary warehouse execution system (WES), at the facility. DATUM enhances the functionality of Meyn’s existing enterprise resource planning (ERP) system, optimizes and directs picking workflows, and interfaces with software and hardware controls for the AMRs and conveyors. The project was completed in six months, meeting Meyn’s target go-live date.

Take a tour of the operation via the video below, with project insights from Meyn’s Michael Otterbach, VP of Parts Operations, and Tom Stanley, Warehouse Operations Manager. They’re joined by Fred Rudolph, DCS’ Senior Account Executive.

Greenfield Facility Leverages Scalable Automation

The trio discuss how the global leader in automated poultry processing equipment sought to ensure rapid shipping by stocking 80% of its parts portfolio and guaranteeing two-day deliveries. Previously, their Georgia-based inventory system faced space constraints and inefficiencies, prompting the shift to automation.

To achieve this transformation, Meyn partnered with DCS to develop a scalable, technology-driven DC. After thorough analysis, DCS implemented a system featuring static racking, AMRs for order picking and put away, and an automated conveyor sortation system. The backbone of the operation is DATUM, DCS’ proprietary WES, fully integrated with Meyn’s ERP. This provides real-time inventory visibility and streamlines fulfillment.

DATUM Optimizes Picking

With DATUM, the picking process has been optimized. Associates use tablets and handheld scanners to verify items, reducing errors while AMRs transport carts efficiently. The facility’s automation extends to packing and shipping, where conveyors and scan tunnels ensure accurate order fulfillment.

Upon go-live, the facility demonstrated improved throughput and efficiency over the previous operation. Order fulfillment errors have decreased, and a 24/7 urgent parts service is now available. The partnership with DCS has been instrumental in achieving these milestones, with Meyn lauding the integrator’s transparent and tailored approach. With automation in place, Meyn continues to refine its global parts shipping process, reducing costs and its carbon footprint.

Hoping to improve inventory visibility, order accuracy, and order fulfillment productivity? Connect with DCS to discover how we can help you achieve your goals.