For four decades, DCS has been providing comprehensive system integration solutions that incorporate a wide variety of material handling equipment and fulfillment automation. As warehouses, distribution centers, and parcel handling operations needs have grown more complex, our team recognized the need for a new breed of warehouse execution system (WES). One built from the ground up, and totally independent from original equipment manufacturers’ (OEM) software. The WES also needs to deliver on the promise of scalability, availability, flexibility, and reliability — a promise where, in our experience, many fall short.

That’s why I and some other hand-picked industry software experts joined the DCS team. DCS offered us the opportunity to craft a new WES that truly meets the needs of today’s supply chain operations. We’re excited to be unveiling our new, proprietary WES — named DATUM — during ProMat 2023 in Booth S3568 in the South Hall of Chicago’s McCormick Place.

What sets DATUM apart from other WES platforms?

Like most WES solutions, DATUM blends warehouse control with tasks traditionally handled by a WMS. It handles order planning, intelligently releases tasks, synchronizes all current work, and continuously reprioritizes it for the optimal process flow. It supports semi-automated or completely automated distribution centers to fill high-velocity orders with specific delivery deadlines. There are, however, several features that set DATUM apart from other WES software in the market.

DATUM integrates easily with virtually every existing software system.

Just as DCS is brand independent, enabling us to design and engineer the optimal solution for our customers, so too is DATUM. Thanks to its flexible, secure API gateway and integration bridge, it easily interfaces with virtually every warehouse management system (WMS) software, including those from all major suppliers, legacy systems, and homegrown solutions. It also interfaces directly with enterprise resource planning (ERP) systems. This enables operations to increase their agility by expanding current capabilities beyond the limitations of any existing WMS software.

DATUM supports modular hardware configurability.

To remove silos of automation, DATUM integrates with a broad range of material handling hardware and warehouse automation. These include:

- Conveyor systems

- Sortation systems

- Autonomous mobile robot (AMR) fleets

- Goods-to-person fulfillment automation

- Light-directed picking

- Automated storage and retrieval systems (ASRS)

- Unit sorters

- Auto-baggers

- Conventional and robotic palletizers

- Voice-directed picking

- Pick and put walls

- Mobile devices

- Automated print-and-apply systems

- Custom cartonization equipment

DATUM also offers native programmable logic controllers (PLC) integration, as well as integration using TCP/IP. These functions allow it to connect with and synchronize new, existing, and modernized material handling equipment.

Completely customizable WES deployment options.

An operation can deploy DATUM in the manner that best suits its needs. Whether hosted in the Cloud, on-premises, or in a hybrid configuration that minimizes the server hardware investment, DATUM provides highly reliable connectivity at the required speed. Depending on the degree of real-time information accessibility needed, DCS software experts can help a facility determine which deployment method works best.

Sophisticated container management functionality.

At its core, the DATUM WES features multiple, sophisticated functions that streamline and manage inventory handling and order flow throughout a fulfillment operation. These include dynamic and intelligent container, inventory, equipment, and order management strategies, such as:

- Buffer lane management

- Consolidation

- Container configuration

- Container lifecycle

- Container routing

- Conveyor and equipment modeling

- Destination mapping

- Dimensioning and weight validation

- Inventory auditing

- Label and print management

- Location inventory management

- Order management and release

- Order soft and hard allocation

- Pick and put order fulfillment

- Pick path optimization

- Replenishment

- Wave release

- Waveless flow

DATUM is a robust, stable, and secure WES platform.

Developed with widely used components that already form the backbone of the systems used by major software and service providers — including Google, Netflix, and Meta — DATUM’s base platform is both innovative and extensively deployed worldwide. Its microservice architecture makes it both robust and well supported, with billions of users continuously improving and refining the source code. Further, by creating DATUM with widely used technologies, the WES is steeped in the latest security protocols and standards. That foundational architecture makes the software extremely dynamic, easily updated and scaled, and highly resilient for maximum solution reliability.

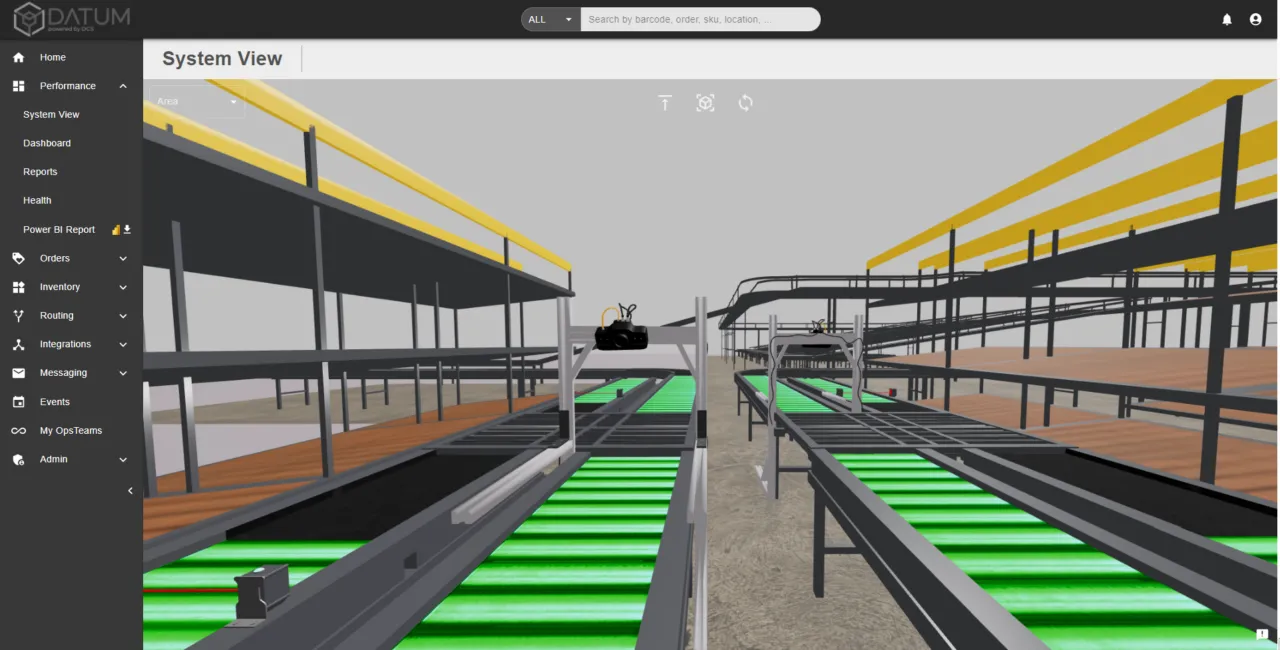

Intuitive user interface makes DATUM easy to navigate.

With a modern, easy-to-navigate, web-based user interface, DATUM provides key business information through full text search across all available data sources. The WES synthesizes and analyzes information in real time to deliver answers — not just data — about key performance indicators (KPIs) in easily understood dashboards and reports. This built-in analytics function helps operations managers quickly pinpoint and address material handling equipment and order issues before they become serious problems, including operating faults and exception handling.

Collaboration functionality enables data sharing.

Managers and other users can share DATUM dashboards and other key points of information internally among personnel with authorized access, as well as externally to others within an operation through Microsoft Teams or Slack. This enables seamless collaboration across workflows, departments, and processes to facilitate faster troubleshooting and issue resolution.

Engage with DATUM at ProMat 2023.

There will be several opportunities for ProMat 2023 attendees to experience the DATUM WES difference throughout the DCS exhibit. Booth S3568 visitors can place an order for one of a dozen DCS giveaways through DATUM, which will direct them to locate the item in a light-directed picking installation. Dashboard displays will show aggregated data about the picks made throughout ProMat, allowing exhibit guests to see real time statistics on swag item velocity. Additionally, interactive kiosks and tablets will allow attendees to explore DATUM’s dashboard creation process, which uses a drag-and-drop interface to support customization.

Can’t make it to ProMat to meet DATUM in person? Connect with us; our software team is happy to schedule a virtual demo.

Author

Brian Curran, Vice President of Software, briancu@designedconveyor.com