Before the pandemic struck in 2020, consumer returns in the retail industry totaled $309 billion in 2019, and online returns represented $41 billion of that total. With the explosion in e-commerce shopping triggered by the spring shutdowns, retail analysts were predicting a 35.8% increase in online holiday purchasing to the tune of $190 billion for November and December 2020, with subsequent returns expected to hit a value as high as $57 billion.

After all, higher online shopping rates naturally beget higher return rates. Consumers return roughly 5% to 10% of purchases made in stores; in contrast, they return 15% to 40% of items bought online. The larger percentages are seen particularly in the apparel categories, where consumers typically buy multiple sizes of the same item, try them on, then return the ones they reject due to size, color, fit, or other reason.

As the online shopping trend has ramped up over the last few years, most retailers – such as omni-channel with both traditional brick-and-mortar storefronts and e-commerce platforms, and those who sell online exclusively – have successfully leveraged technologies to streamline customers’ return experiences. To remain competitive, it’s now table stakes to accept customer returns in person at their own store (or a partner’s outlet: think Amazon and Kohl’s), or via parcel shipment picked up by a carrier or dropped off at a locker, carrier retail outlet, or via mail.

Fewer, however, have directed quite as much energy into establishing their own internal reverse logistics processes for handling the returns once they arrive back at the warehouse. Yet that’s where the real heartburn can begin. Why? Because handling returns is not inherently operationally efficient, as they require tremendous amounts of physical space and manual labor to process.

First, all those returned parcels require space for storage prior to being opened. Then, the manual work occurs. Highly trained operators must open the packages, assign them a tracking number and barcode, and examine and/or test the items inside. Decisions about what to do next are based on a variety of factors, such as the product’s condition, age, any obvious damage or defects, seasonal category, and other qualifications. Based on those determinations, the worker assigns each item a disposition destination. These can include:

- Return the item to inventory for immediate sale.

- Repackage the item for resale in a secondary channel, such as the retailer’s own outlets or at via a discount retailer.

- Repair, refurbish or remanufacture the item (most frequently with electronics).

- Return the item to the original manufacturer, supplier or vendor if there’s an agreement to do so with unsold seasonal products.

- Recycle or dispose of the item if it is damaged beyond repair.

Faced with a mountain of returns that’s only getting larger, retail warehouse and distribution center operators are under extreme pressure to decide how best to handle this monumental task. Some choose to avoid the challenge completely, electing to outsource some or all returns handling to a third-party logistics (3PL) service provider. Others – particularly larger retailers – have the resources to design one (or more) facilities dedicated solely for reverse logistics.

Those two options, however, may not be right for every company. For myriad reasons, an organization may instead elect to integrate returns processing into an existing facility. The principal challenge in making this decision is determining how to adapt part of an operation originally designed to maximize throughput of outbound shipments to enable handling of inbound returns. (Additionally, robust inventory management software is also necessary to track and control the returned items upon receipt and after dispositioning – but that’s a topic for another post.)

There are three strategies most commonly deployed when incorporating reverse logistics into current operations:

- Designate an exclusive area for manual returns processing. For operations that have a limited number of items to handle, this may be the most cost-effective and efficient way to integrate a reverse logistics process into an existing facility. It requires floorspace, as well as workstations for operators to use as they assess the returns. Shelving, racks, carts, totes, putwalls and other basic equipment can be dedicated to this task. Some operations elect to integrate transport conveyor to and from this area to facilitate product movement before and after the dispositioning process for routing to the appropriate destination. Others assign operators to carts of products for manual return to stored inventory or other locations.

- Repurpose existing equipment for part-time returns use. Facilities that have automated equipment already in place for outbound shipment processing – such as conveyors and sortation systems – might consider programming the equipment to be used temporarily for returns handling during a second or third shift. This approach utilizes existing automation, typically tilt-tray or cross-belt sorters, for inbound buffering and routing of returns back into inventory or other disposition locations for a limited period of time.As a solution, this strategy works best for operations that lack the floorspace or capital to add a separate automated system dedicated to reverse logistics. It does, however, require some fairly complex software manipulation and programming to successfully change over the function of the automation from outbound to inbound waves.Additionally, the switchover between the two processes is likely to require a daily commitment of time to ensure all the outbound items are cleared from the system before the inbound returns are inducted – and vice versa – to eliminate any confusion. It also may eliminate the opportunity to pre-stage the sorter or conveyor for the next outbound shipping shift. It also does not eliminate the manual dispositioning process, but rather helps manage excessive volumes.

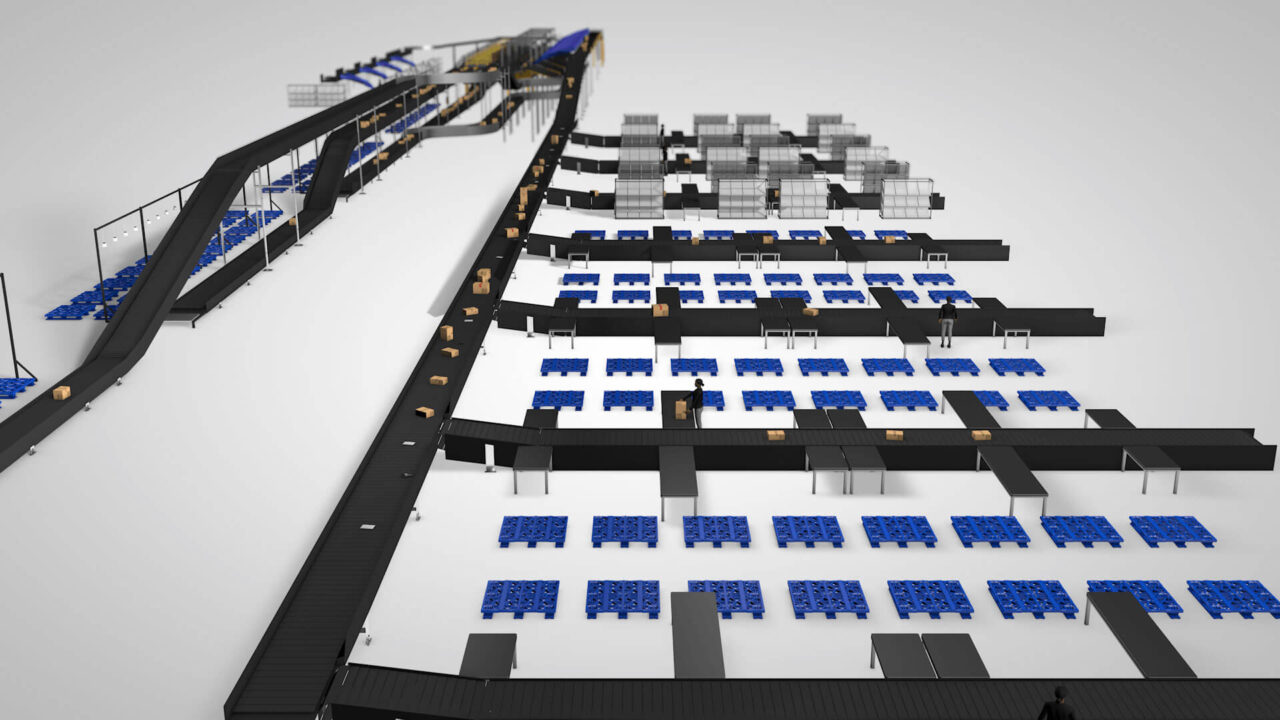

- Invest in a fully automated solution dedicated exclusively for handling returns. Automated shuttles or cube storage systems, for example, can be utilized to sort and store manually dispositioned returns in a high-density footprint, minimizing manual handling after the items have been evaluated and classified. These systems facilitate the organization and storage of items, as well as their tracking and inventory management. When a critical mass of returns has been collected in the system, the automation – working in conjunction with the facility’s warehouse management system (WMS) or warehouse execution system (WES) can create a task for the items to be returned to saleable inventory or sent to a palletizer for shipment back to the original vendor, for instance. This option maximizes both the speed and available storage capacity for handling high volumes of returns in a minimal footprint.

Based on current e-commerce trends, retailers who prefer to handle returns in-house should consider which of these three reverse logistics strategies will work best for their operation – whether they’re considering construction of a new fulfillment center or the expansion or retrofit of an existing facility. Need help figuring out how best to handle returns in your operations? Connect with us.

_

Author

Satyen Pathak, Account Executive, satyen@designedconveyor.com

Satyen Pathak, Account Executive, satyen@designedconveyor.com

As an SME in material handling, Satyen has an extensive background in creating solutions for the retail/e-comm, Parcel, Post, and baggage handling market verticals. He has worn several hats including Product Management, Applications Engineer, Technical support and most recently as an Account Executive with DCS. Satyen has conducted numerous educational speaking engagements and has sat on committees for MHI providing directional insight for the industry.

Satyen Pathak, Account Executive,

Satyen Pathak, Account Executive,