Third-party logistics (3PL) service providers have become increasingly relied upon across a broad range of industries over the past decade, with some of the largest growth coming from e-commerce retailers. Whether they’re small start-ups expanding their reach that don’t need the floorspace of an entire warehouse, or large, multi-store retailers focused on their own core competencies, partnering with a 3PL delivers myriad benefits.

Likewise, the service offerings 3PLs provide have evolved in the past 10 years. Originally dedicated to largely offering contract warehousing for storage and handling of pallets, as consumer and business purchasing patterns have shifted, so too have the predominant unit types 3PLs are handling today: from full and mixed pallets to cases and eaches.

It’s a common refrain amongst 3PLs whose businesses focus primarily on the retail and e-commerce. I surveyed organizations who shared these supporting statistics, aggregating outbound handling per pick type across multiple customers who represent similar retail verticals and market channels:

- In 2010, pallet picks represented 65-70% of this 3PL’s outbound handling versus 25-30% case picks and 5% each picks.

- In 2020, with the uptick in e-commerce, pallet picks are just 5% of this 3PL’s operation, versus 65-70% case picks and 20-25% each picks.

The increased demand for handling smaller and smaller case and unit quantities directly translates into an increase in the amount of labor required to fill orders. The same 3PLs noted:

- In 2010, labor spent 15-20% of its time on pallet picks, 70-80% on case picks, and 0-5% on unit picks.

- In 2020, labor has shifted to spending 0-5% of time on pallet picks, 40-50% on case picks, and 50-60% on unit picks.

Like the rest of the warehousing and distribution industry, 3PLs are not immune to the labor shortages that challenged operators in the run-up to the onset of the coronavirus pandemic. They too struggle to attract, hire, and retain talent against relentless competition from neighboring facilities offering higher hourly wages and from the lack of interest in such jobs by younger generations entering the workforce. Starting wages have skyrocketed from $10 an hour in 2010 to upwards of $20 an hour for similar jobs in today’s marketplace.

Meanwhile, service level agreements (SLAs) have only become more stringent. That’s because – in order to remain competitive in their respective markets – 3PL customers increasingly need next-day or same-day shipments and have ever higher expectations for near-perfect order accuracy.

Automation Complements Manual Operations

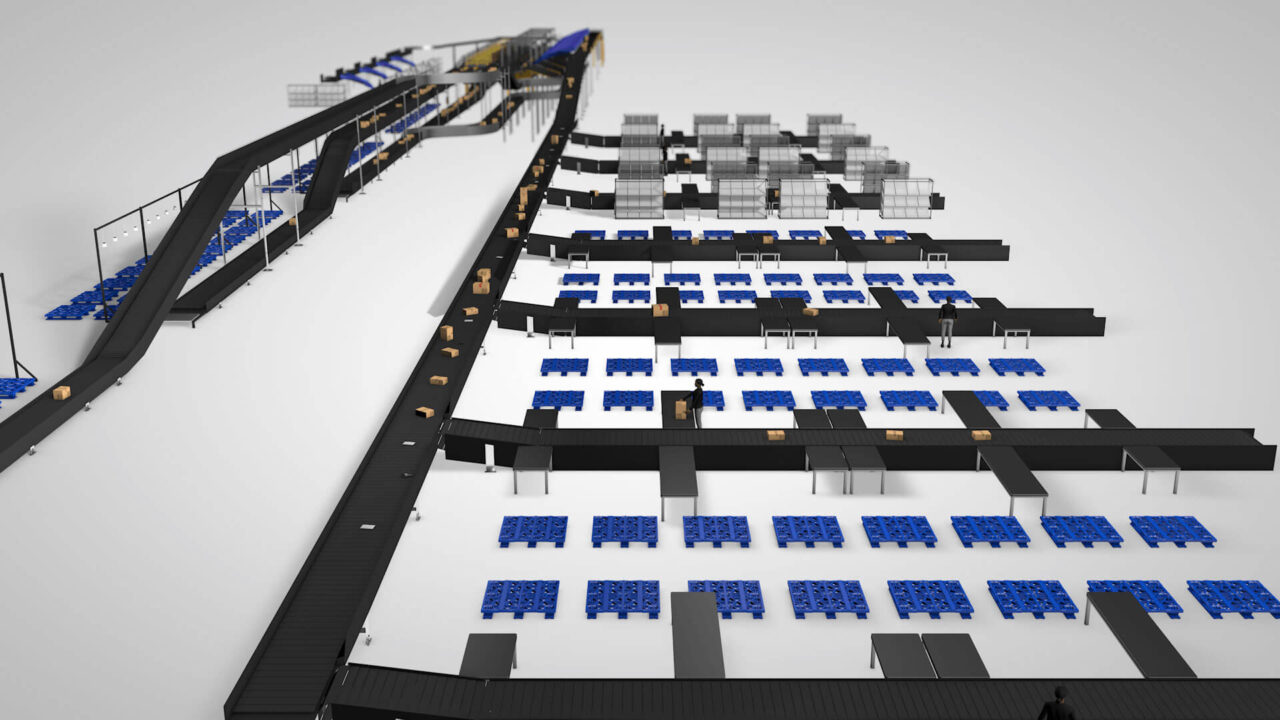

With all this to consider, more 3PLs are turning to semi-automated and fully automated solutions as an alternative to increased headcounts in order to best support their customers’ businesses and expectations. These technologies, many of which are designed to enhance human productivity and eliminate non-value-added tasks, can easily accommodate an increase in throughput at a near-perfect degree of accuracy. That makes them more attractive to warehouses and fulfillment centers, including those operated by 3PLs.

Yet, with the average 3PL-client contract spanning three to five years, large-scale automation investments – such as complex, fixed solutions like automated storage and retrieval systems (ASRS) – typically don’t deliver a return on investment (ROI) fast enough to justify the capital expenditure. Instead, the optimal automated solutions for 3PLs are those that check three boxes: scalable, flexible, and quick ROI.

Scalable solutions can be ramped up over time to accommodate growth customers and defer capital investment until needed, increasing cash flow. Flexible automation allows handling of the unknown volume fluctuations and hockey stick peak volumes. Flexibility is also key to preventing huge amounts of excess investment and capacity for the majority of the year. With the rise in wages, mechanization and automation have become more attainable and attractive. Technological advancement is driving down required investments and opening the door for 3PLs to automate.

In my next post, I’ll discuss some of the winning automated solutions – including autonomous mobile robots (AMRs), light-directed putwalls, and software – that are helping 3PLs meet shifting customer expectations by increasing their efficiency. I’ll also explore how these solutions are delivering ROIs within 18-24 months.

Want to learn more about how DCS can create a scalable and flexible e-commerce handling solution for your 3PL, warehousing or distribution operation with an attractive, short-term ROI? Connect with us.

_

Author

Scott Singer, Systems Sales Consultant, scott@designedconveyor.com

Scott Singer, Systems Sales Consultant, scott@designedconveyor.com

A 10 year veteran of the 3PL and material handling world, Scott’s career has been focused on solutions engineering and design, business development, and sales consulting. Scott spent most of his career developing cost saving innovative designs for 3PLs and their clients. He leverages this experience to help 3PLs generate flexible high return solutions. In his free time, Scott spends his time exploring the four corners of the world in culture and the great outdoors.

Scott Singer, Systems Sales Consultant,

Scott Singer, Systems Sales Consultant,