When most people think about engaging a consulting partner for help in resolving a warehousing, distribution, or fulfillment network issue, they typically focus solely on resolving that specific problem. Some operations, however, bring in a consultant (or consulting firm) to help them determine how to better align their supply chain execution with their organization’s overarching strategic business goals. This, in effect, puts the consultant in the role of business coach.

As the world has now learned — thanks to the pandemic — the success or failure of an organization’s supply chain can have a huge impact on daily life, as well as on the bottom line. Recognizing that criticality, larger companies have increasingly added Chief Supply Chain Officers (CSCO) to their leadership ranks. But whether a CSCO is in place or not, a warehousing or distribution consultant offers an unbiased, third-party perspective on where operations currently stand, identify opportunities for improvement, and make recommendations that better position the organization to reach its objectives.

Not every warehouse or distribution consultant is necessarily qualified to offer bigger picture guidance, however. Some are extremely specialized, dealing solely with software or tackling isolated engineering challenges. Others may lack an adequate amount of relevant business experience, depending on their background or years of tenure within the field. When evaluating potential consulting partners for a project with big picture implications, consider their portfolio of service offerings, years of experience, areas of expertise, the types of projects they’ve worked on previously, and references.

Consulting Engagements That Impact Business Strategy

While consultants can be engaged to provide a variety of different services, there are a few projects that can have a particularly significant impact on a company’s overall strategic goals. These include:

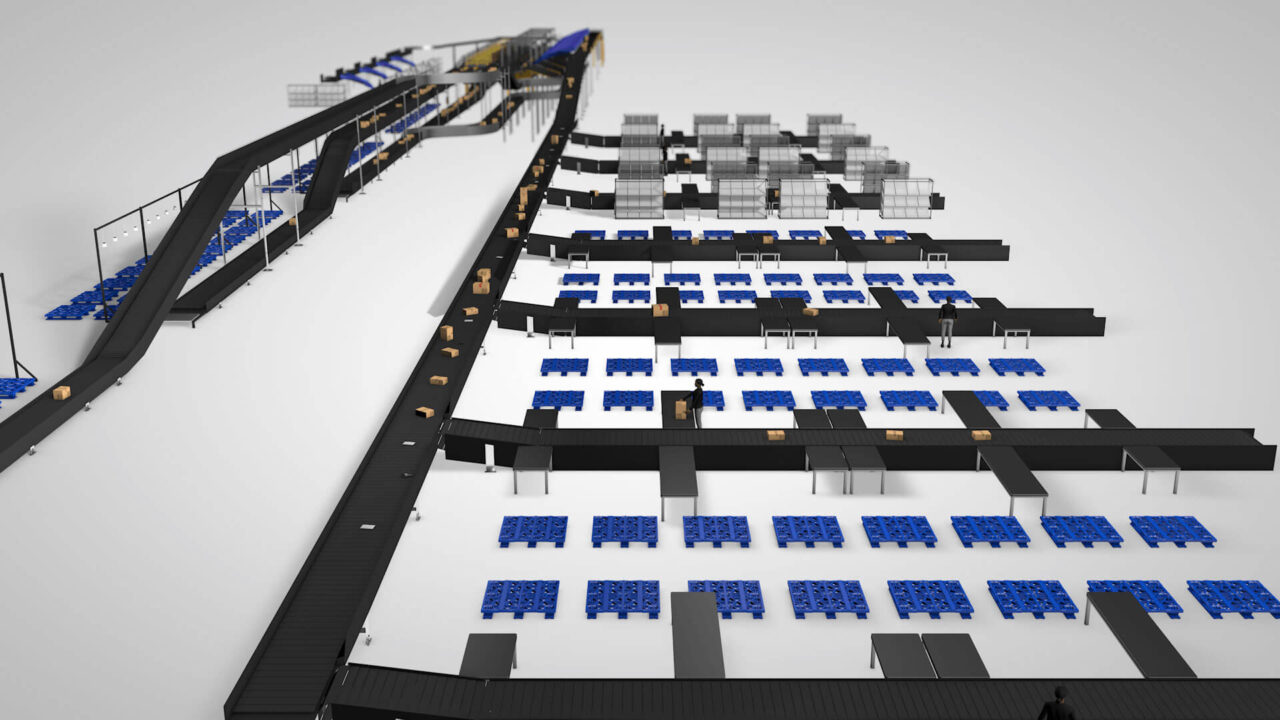

Operational assessments are a type of analysis that evaluates an operation’s existing processes, equipment, software, systems, layout, personnel, inventory mix, handling practices, and more. Based on the findings, the consultant will identify opportunities for improvement to the current state, as well as to bring the operation into better alignment with business goals and strategic projections over the next three to five years. The deliverable typically includes recommendations about how to address these goals, from the simplest measures (people and process management) to the most complex and expensive (investments in equipment, software, or systems). The resulting growth in productivity, efficiency, capacity, throughput, or other measurable objective should be tied into the overall organizational strategy.

Network logistics studies determine the optimal geographic location of a new distribution center, or of every distribution center within an operation’s portfolio. These are often undertaken when an operation has outgrown its current facility or is seeking to expand into a new region. They’re also frequently performed in the aftermath of a merger or acquisition, when two or more warehouses or distribution centers overlap in inventory, geography, or customer base. Because the goal of a network logistics study is to determine which location(s) have the lowest total landed supply chain costs — from acquisition to shipping to customers — they have a significant impact on a company’s overarching business goals.

Leadership evaluations are something I personally have been asked to do more frequently in recent years, typically in conjunction with either operational assessments or network logistics studies. These engagements include both a quantitative analysis of management staff in terms of their operations’ respective performance, as well as a qualitative assessment of each individual’s skills and potential.

Notably, every CEO or CSCO who has requested this service did so not because they were looking to fire members of their team, but rather with the intent to better match their current supply chain leaders’ skillsets with best-fit opportunities. With the recent hiring and retention challenges experienced by so many organizations, those at the executive level are looking to position their people in the roles that suit them best, as well as offer them opportunities to advance their skills and grow within the company. Having an independent, third-party provide an unbiased opinion and strategic staffing recommendations can help to strengthen a company’s overall competitiveness, as well as better support the organization’s objectives.

Thinking of hiring a consultant to help your operations better align with your overarching business goals? To learn more about working with DCS, connect with us.

Author

Mark Kidwell, Director of Supply Chain Consulting, markk@designedconveyor.com

With over 35 years in the material handling industry, Mark Kidwell provides valuable solutions for our clients regarding operations and process improvement, labor efficiency, DC design, and inventory management consultation.