With consumers worldwide turning to e-commerce and online shopping in 2020 out of necessity due to COVID-19 lockdowns and continuing to embrace that convenience as the pandemic surges and ebbs, retailers were thrown into a tailspin trying to keep up. Brick-and-mortar stores shuttered (and continue to do so, although currently at a slower pace according to Coresight Research), while warehouse stock keeping unit (SKU) counts rose 21.7%, as found by a Peerless Research survey.

This increase in demand for direct-to-consumer shipments and buy-online-pick-up-in-store (BOPIS) offerings posed multiple challenges for retail fulfillment operations – both those selling hard and soft goods and in grocery outlets. Perhaps the two largest challenges were the struggles to attract, hire, and retain an adequate workforce to help fill orders in a timely manner, and to ship those orders in alignment with shoppers’ expectations while managing costs.

Enter the Dark distribution center, or Dark DC. While the concept has been kicking around for a while, not many operations were able to justify an investment in one or more fully automated, lights-out facilities with minimal staffing requirements. At least not when labor was more affordable and more available.

With the pressures driven by COVID-19, however, retailers are increasingly looking to deploy more automation in more locations to alleviate workforce challenges. They’re also transitioning away from having a few mega-DC locations within their networks to multiple, smaller footprint facilities (outfitted with automation) located closer to end customers to reduce delivery speed and distance.

Indeed, findings from a study conducted by Researchscape International found that in 2021, 50% more retailers plan to fully automate their fulfillment locations, including Dark DCs/stores, pop-up (short-term lease) DCs, and micro-fulfillment centers (often in the backroom of an existing brick-and-mortar retail outlet). Looking ahead 24 to 36 months, the report notes:

Over the next 2-3 years, retailers’ usage of pop-up DCs will double, rising from 12% of networks today to an expected 26%; dark stores will double from a small base, growing from 6% of networks today to 12%; and micro-fulfillment centers will nearly double, rising from 15% of networks today to 27%.

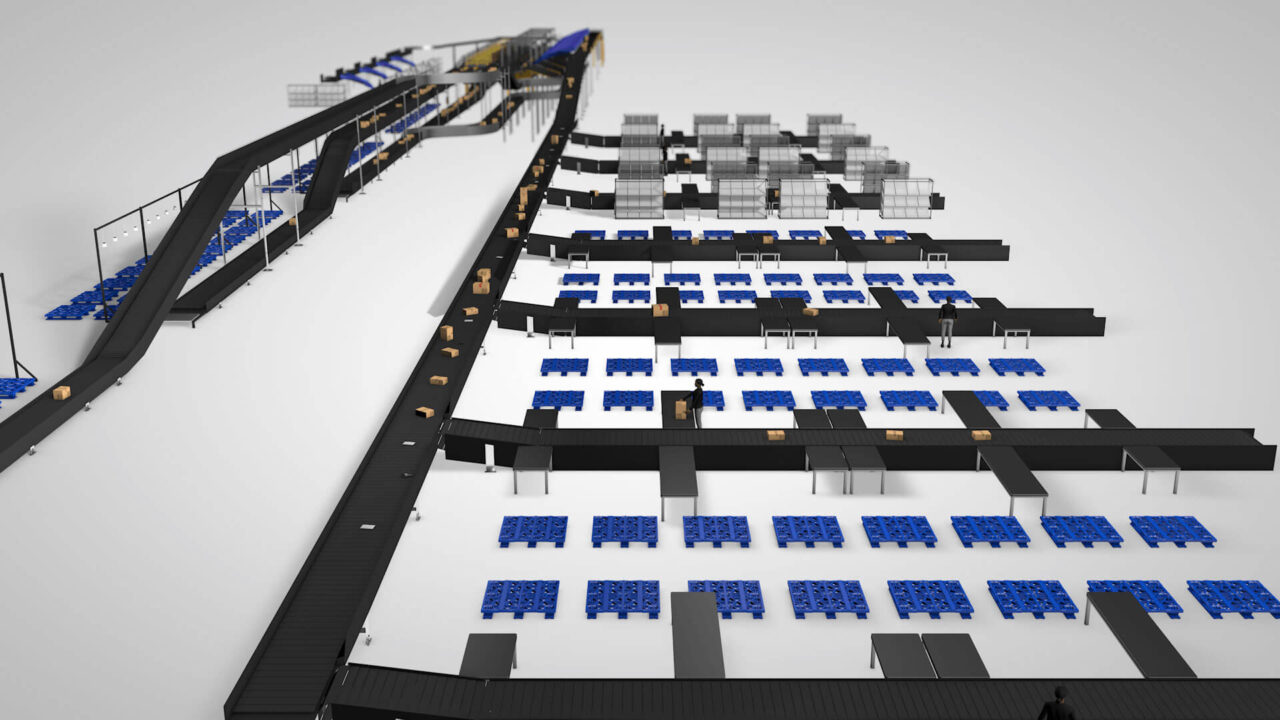

Implementing automation – such as crane or shuttle-based automated storage and retrieval systems (ASRS) that store the fastest-moving, most frequently ordered SKUs; goods-to-robot or goods-to-person picking and packing stations for selection of items; and autonomous mobile robots (AMRs) or automatic guided vehicles (AGVs) that deliver the packaged orders to outbound delivery vehicles – dramatically decreases reliance on labor.

With these automated solutions, a traditional workforce of hundreds of pick-and-pack workers walking up and down conventional warehouse aisles to fill orders is no longer needed. Instead, only a few workers are required to fill and pack orders (or, in a truly Dark DC, robotic picking arms replace human pickers), plus the staffing of a few key positions – such as maintenance technicians and managers – in the operation. With rising wages and the expenses associated with training new hires in a high-turnover field, the investment in these solutions increasingly pencils out for more retailers.

Additionally, because the automated solutions are engineered to store a maximum number of SKUs in a highly compact, dense configuration, Dark DCs require a considerably smaller footprint than a traditional fulfillment operation. That allows them to be located in non-traditional square footage. Shuttered storefronts and anchor stores in malls and downtown urban cores are prime locations, as they are located in densely populated areas.

Such proximity permits a grocer or retailer to provide same-day delivery to a consumer’s home or to a nearby retail outlet for pickup by the purchaser both considerably faster and more affordably than shipping from a centralized, large-scale DC. Further, many retailers are locked into leases or ownership of these closed stores; converting the unused space into Dark DCs allows them to leverage that investment.

To make a Dark DC fulfillment strategy work, it’s critical to have effective warehouse management system (WMS) software in place. With the right WMS, a company can continually analyze the velocity of SKUs across geographic locations, ensuring that the right mix of inventory is stocked in the right regions to match consumer demand. Additionally, a WMS updates inventory levels in real-time while improving visibility throughout the network. It also allows a company to provide accurate delivery estimates for ordered items to guarantee customers’ expectations are met – which is, of course, the primary objective of the Dark DC concept for today’s retailers and grocers.

What do you think? We’d love to hear your thoughts on this topic. Connect with us.

_

Author

Satyen Pathak, Account Executive, satyen@designedconveyor.com

Satyen Pathak, Account Executive, satyen@designedconveyor.com

As an SME in material handling, Satyen has an extensive background in creating solutions for the retail/e-comm, Parcel, Post, and baggage handling market verticals. He has worn several hats including Product Management, Applications Engineer, Technical support and most recently as an Account Executive with DCS. Satyen has conducted numerous educational speaking engagements and has sat on committees for MHI.

Satyen Pathak, Account Executive,

Satyen Pathak, Account Executive,