This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

PART 2: The Retailer’s Guide to Efficient and Effective Distribution Network Optimization

The first installment of this two-part post examined the challenges faced by retailers in need of a distribution network optimization, the goals for such a project, and the benefits. This, the second part, details the key components involved and the strategies the optimization supports for a more efficient retail distribution network.

Key Components of a Retail Network Optimization

By leveraging data-driven optimization techniques — including analytics and supply chain modeling for distribution network optimization — retailers can create a streamlined, cost-effective, and customer-centric distribution network that supports long-term growth and competitiveness. There are three key components involved in the examination.

- Data Analysis

To build a baseline against which potential network scenarios will be compared, a network optimization process requires historical operational and financial data. Information for assessment includes a year of inbound and outbound order history, inventory levels, transportation expenses, and shipment costs. Additionally, the data analysis also includes a growth forecast and details from the company’s strategic plan for the next 10 to 15 years.

- Network Design Modeling

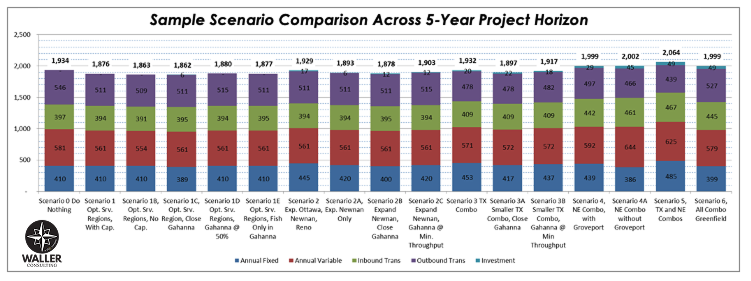

Based on the data inputs, a current state model is built and then manipulated to simulate different network design scenarios. These might include plotting different numbers and locations of distribution centers (DCs) to achieve different possible service levels and operating costs. The modeling process also takes inventory locations into account when considering what products to locate where. With just 20% of the majority of retailers’ inventory producing 80% of sales, where that 80% is stored is critical to controlling costs within the retail distribution network. In general, a multitude of network design scenarios are considered in the process of identifying which is optimal.

- Technology Assessments

Another part of a retail network optimization project is assessing the material handling hardware and management system software already in place in existing facilities. This includes an evaluation of current processes, deployed automated solutions, and software — such as warehouse management systems (WMS), warehouse execution systems (WES), transportation management systems (TMS), labor management systems (LMS), and more. The technology assessment provides greater insight into how consistently each DC within the network operates relative to the others. It also can highlight issues surrounding the ease of information sharing (specifically surrounding inventory availability) across the network, which is critical to improving efficiencies and enhancing customer service levels.

Winning Strategies for Optimizing Retail Distribution Networks

When considering a retail distribution network optimization, there are several tactics that can be deployed. These include:

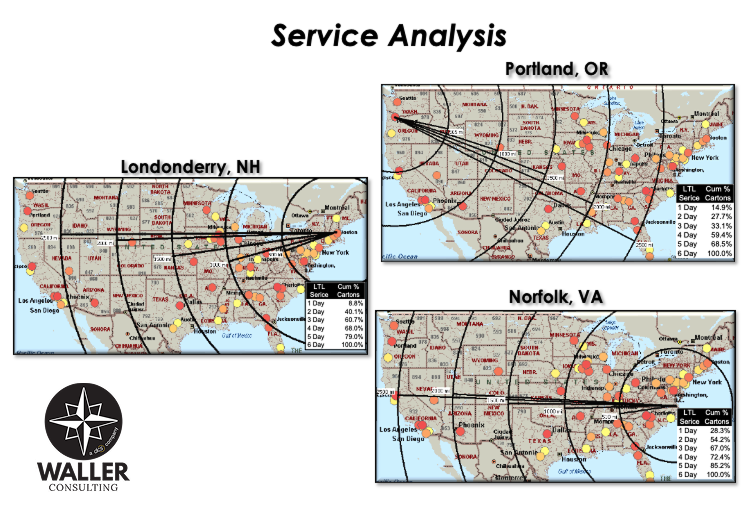

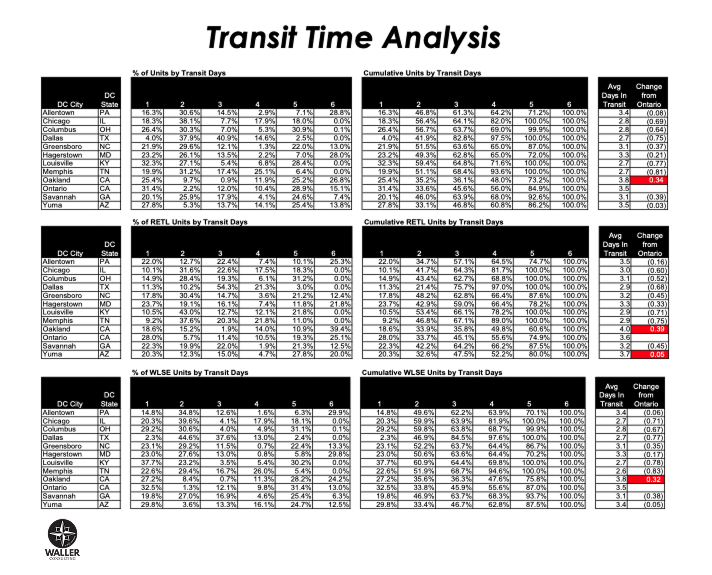

Appropriate Warehouse and DC Placement

In order to determine optimal locations for storage and fulfillment centers, different DC location scenarios will be examined as part of the distribution network optimization. For example, how to locate DCs so a retailer can fill every e-commerce order in the U. S. via ground shipping within a two-day window. Or — as an alternative to filling orders in California from a DC in New Jersey in six days — should a new DC be established on the West Coast to serve customers on that side of the country with two-day ground shipping. Additionally, as many retailers have grown through mergers and acquisitions, there is frequently more than one warehouse in the same region; this redundancy contributes to inefficiencies and costs. The location assessment will evaluate the viability of those operations as well.

Proper Inventory Amounts and Allocation

From an inventory strategy perspective, optimizing the retail distribution network ensures the right products are in the right locations. One optimization option is to centralize slow-moving products to streamline operations and reduce costs. This approach follows a hub-and-spoke model for certain inventory classes. The auto parts industry does this routinely. Rather than stocking rarely ordered parts in every facility, they are consolidated in a single location. Conversely, high-turnover items, such as spark plugs, are stored at forward-facing locations to efficiently meet demand. This optimization strategy can be implemented regionally or across multiple slow-moving facilities, allowing businesses to reduce the size of their DCs and centralize inventory, leading to cost savings.

Deployment of Cloud-Based WMS Software

A WMS provides highly granular insights into inventory, and functions as a control hub with real-time operational oversight. Further, many modern WMS solutions are cloud-based, enabling multiple facilities to connect to the same system. This means warehouse A can access warehouse B’s inventory, and vice versa, facilitating seamless inventory transfers when configured correctly. Beyond tracking, a WMS supports retail distribution network optimization by initiating inventory transfers, integrating with the host system to ensure data consistency across all operations. This supports holistic, unified inventory management. Finally, a unified WMS facilitates operational consistency and standardized handling processes across multiple locations, enhancing efficiency and accuracy.

Streamlined Transportation and Logistics Planning

By strategically positioning DCs closer to key markets, businesses can minimize the distance goods must travel. This leads to faster deliveries while lowering fuel and labor expenses. It also reduces the need for expedited freight and shipping. Further, a network optimization that includes deployment of a TMS significantly improves transportation and logistics by integrating real-time tracking and predictive analytics, retailers gain greater visibility into retail logistics operations. This enables proactive decision-making and planning. A TMS can also support streamlined delivery routes, reduce transit times, and lower costs through route optimization and shipment consolidation to maximize truckload utilization and reduce empty miles. It also facilitates coordination with last-mile delivery providers to improve on-time delivery rates for higher customer satisfaction.

Collaborating with Suppliers and Partners

Partnerships with suppliers and service providers — particularly for retailers who rely heavily on imported goods — can enable other distribution strategies that bolster flexibility and efficiency. For example, retailers can postpone inventory allocation decisions until a containerized shipment from overseas reaches a break-bulk facility. Although many retailers outsource this task to third-party logistics (3PL) service providers, an optimized retail distribution network could let them bring the process in-house. In addition to reducing per-unit shipping costs by consolidating orders into full ocean container loads, delayed allocation enables real-time decision-making. The retailer could then distribute inventory based on actual demand rather than forecasts, dynamically directing goods to regions of highest demand. This reduces the risk of overstocking in one location while facing shortages in another, improving overall supply chain efficiency.

Leverage Waller Consulting’ Expertise on Your Retail Network Optimization

Gain unbiased insight into how to optimize your retail distribution network from an independent, third-party consulting firm. The consulting team at Waller Consulting, a subsidiary of DCS, brings a combined 90-plus years of hands-on expertise helping operations in both commercial and government sectors optimize performance, efficiency, and profitability. To discover how we can help your organization minimize costs, reduce delivery times, and enhance customer satisfaction through strategic supply chain distribution network optimization, connect with us today.