It’s no secret that technology is going to continue to evolve at a high rate of speed. This applies to the vehicles we drive, the phones we use, and the way we consume various forms of media.

Autonomous cars are already being tested on our streets. This advancement was once thought to be so far on the horizon that we might never see it. However, the existence of this technology points to the fact that our innovations are moving along at a faster pace than much of us realize.

This also applies to warehouse automation. This industry has made some great strides over the last decade, and this trend is going to continue into the future.

This is going to create a lot of opportunities to streamline various processes. And warehouse automation is an industry that is primed to make use of these advancements.

Here are some of the ways warehouse automation will progress and support warehouses moving forward:

- Increased Demand

- Continued Ingenuity

- Streamlined Processes

- Warehouse Management Technology

- Tangible Benefits

Increased Demand

Customer patience is famous for shrinking over time. And as people become more accustomed to getting the items they want quickly, an increased focus on this ability will push the technology.

Consumers are already used to Amazon’s two day shipping. This has become so ubiquitous that it’s fast becoming the standard. Many companies are looking for ways to compete with such a service and get items into the hands of their customers faster.

Shipping directly to customers’ doors isn’t always necessary, but speed of transfer – even to stores – is going to continue being a focus moving forward.

Continued Ingenuity

Technology doesn’t stop its movement toward the future. This is true for every industry. Even publishing – the act of reading a book – has been addressed with continued advancements in technology. No industry is immune to the progress of the human mind.

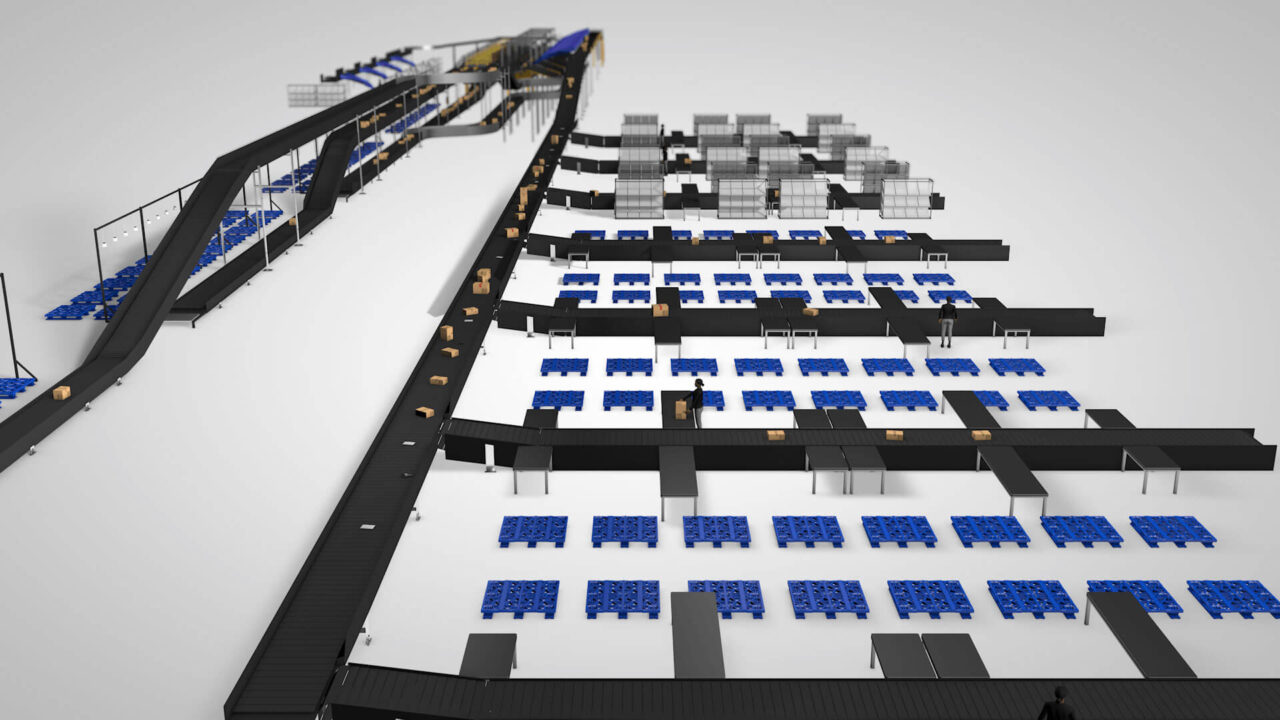

Warehouse automation is already at a very respectable place. There are picking and sorting systems that have greatly improved on the processes of the past. Intelligent conveyor systems have made transferring items much easier than could have been imagined a generation ago.

And this trend is going to continue to integrate new technologies in interesting ways to help warehouses achieve maximum efficiency.

Streamlined Processes

This efficiency is the main goal. There are a lot of moving parts within a successful warehouse. The ability to get all of these parts to line up and work together will be what separates warehouses of the future and warehouses of the past.

Everything from inventory, to picking, to sorting, to shipping will need to be synchronized. This difficult task will be made much easier with future versions of warehouse automation.

Autonomous picking robots are already being integrated into various industries. This technology will be perfected over time.

Warehouse Management Technology

There are a series of tasks within a warehouse that don’t have anything to do with physically finding, arranging, and sorting materials. However, these tasks are what set the infrastructure so the physical tasks can be completed as efficiently as possible.

These tasks can be tracked, updated, and compiled with the help of warehouse automation. This includes using barcode scanners to capture information which can then be tracked. This can be used for considerations such as updated inventory counts, or even tracking down misplaced packages.

Management technology is what sets the stage for a successful warehouse. Further advancements in this technology will make everyone’s jobs much easier.

Tangible Benefits

There are a lot of people that are resistant to change. These advancements can create a lot of questions in people’s minds as to how this will affect the warehouse industry – and its workers – moving forward.

These advancements are going to help everyone involved – from the warehouse employees, to the customers, to the business as a whole. Here are some of the ways this will happen:

Safety

Accidents are bound to happen even in the safest warehouses. This usually happens either when there’s a mechanical failure, or people are where they shouldn’t be. Increased warehouse automation will clear the pathways that formally posed a risk.

Accuracy

Manual errors lead to product losses and delayed shipments. Automation is much less likely to make the same errors, diminishing time lost to incorrectly labeled or stored items.

Efficiency

Automated systems are designed to locate packages quickly, and this ability is only going to grow stronger. An elimination of delays and mistakes will get the jobs done quicker, making the warehouse operate much more efficiently.